| Title | Valorization of cocoa pod side streams improves nutritional and sustainability aspects of chocolate |

| Authors | Kim Mishra, Ashley Green, Johannes Burkard, Irina Gubler, Roberta Borradori, Lucas Kohler, Johannes Meuli, Ursina Krähenmann, Jotam Bergfreund, Armin Siegrist, Maria Schnyder, Alexander Mathys, Peter Fischer & Erich J. Windhab |

| Journal | Nature Food |

| Year | 2024 |

| URL | https://www.nature.com/articles/s43016-024-00967-2#Abs1 |

What do the films Willy Wonka, Matilda, and Chocolat have in common? They all iconically feature one of the world’s favorite sweets – chocolate. 🍫

Commercial chocolate is typically a mixture of cocoa beans (extracted from cocoa pods) and sugar beets. Farmers harvest the cash crop year-round, cracking open the pod to reveal the important cocoa beans…and then discard the empty husk. This contributes to a huge amount of organic waste – about 700k tons annually! But what if you could use the outer layer as part of the chocolate-making process?

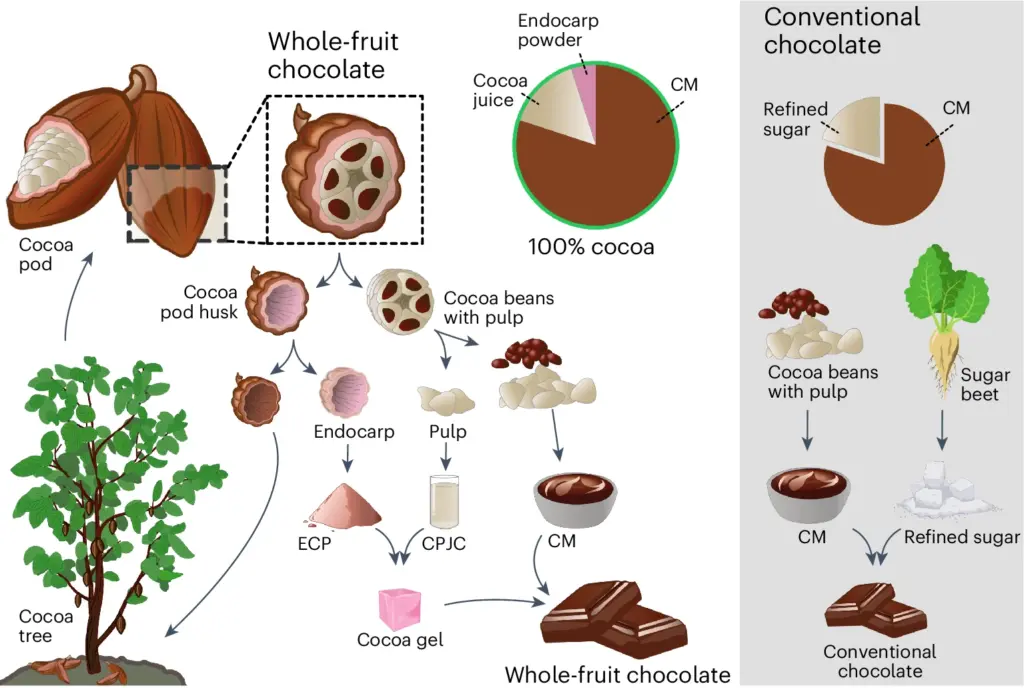

Swiss scientists asked this very question and studied how to transform the entire cocoa fruit into the sugary confectionary in a practice called circular economy (Fig 1). Using every part of the cocoa fruit would help to lower the overall environmental impact of cocoa farming, diversify the economic activities of its farmers, and support the cocoa business in major export countries such as Cote d’Ivoire, Ghana, and Ecuador.

The new chocolate production process would replace the refined sugar component of current chocolate with a sugary mixture made of the cocoa pod components. First, the scientists extract the interior material of the cocoa pod – the beans and the pulp. Some of the pulp is pulverized with the cocoa beans to make the chocolate mixture (CM). The unused pulp is ground into a sugary juice (cocoa powder juice concentrate or CPJC). The scientists then turn their attention to the discarded cocoa pod and extracted the endocarp – a woody inner layer that typically surrounds the seeds of a fruit, like the stone of a peach – from the outermost husk. The juice is combined with the endocarp powder (ECP) and turns into a sugary gel, which results from the high level of pectin contained in the endocarp (~12-14% weight % of pectin). This gel sweetens the cocoa bean paste and leads to a tasty chocolate bar.

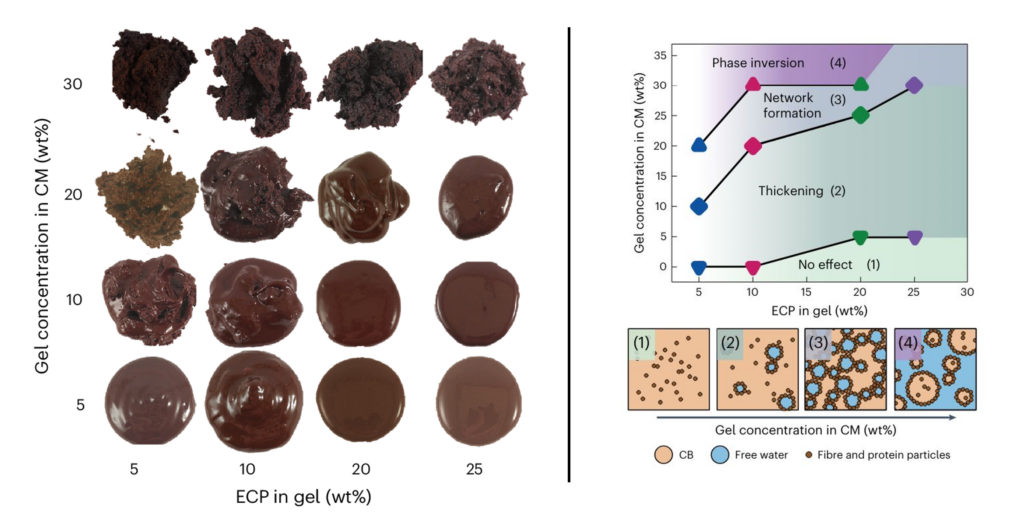

Well, at least that was the theory… but the scientists had to optimize their recipe. In particular, they had to figure out what impact the quantity of endocarp in the gel – and how much gel in the chocolate – would have on the properties of the final confection. Different combinations of ECP and juice changed the chocolate’s glossiness, thickness, and stability, resulting in either appetizing or unappealing confections (Fig 2 left). Too much gel created matte and crumbly chocolate, while too much ECP in the gel produced flat but glossy chocolate drops.

The scientists theorized that this drastic change was due to the swelling of the fibrous material in the chocolate bean mix (the mixture of cocoa beans and pulp) by the water entrapped by the gel in colloidal particles. Colloids are suspensions of particles in a solution (like milk), which is reflective of what chocolate really is – a mixture of proteins, small molecules (like caffeine) and carbohydrates in water and fat (i.e. cocoa butter). At low gel concentrations, the available water is absorbed into the chocolate bean paste (CB) and integrates fully, leading to a smooth and glossy appearance. At higher gel concentrations, the pectin in the endocarp-gel entraps the water in colloidal-particle-like-biofibers and cause the mixture to thicken. At the highest gel concentrations, the swollen biofibers create strong bonding networks and lead to phase inversion, going from glossy liquid to crumbly solid (Fig 2, right). One could imagine an ideal gel/endocarp recipe would produce chocolate bars with a glossy appearance but thicker texture, although that ideal could change depending upon the chocolatier’s intention.

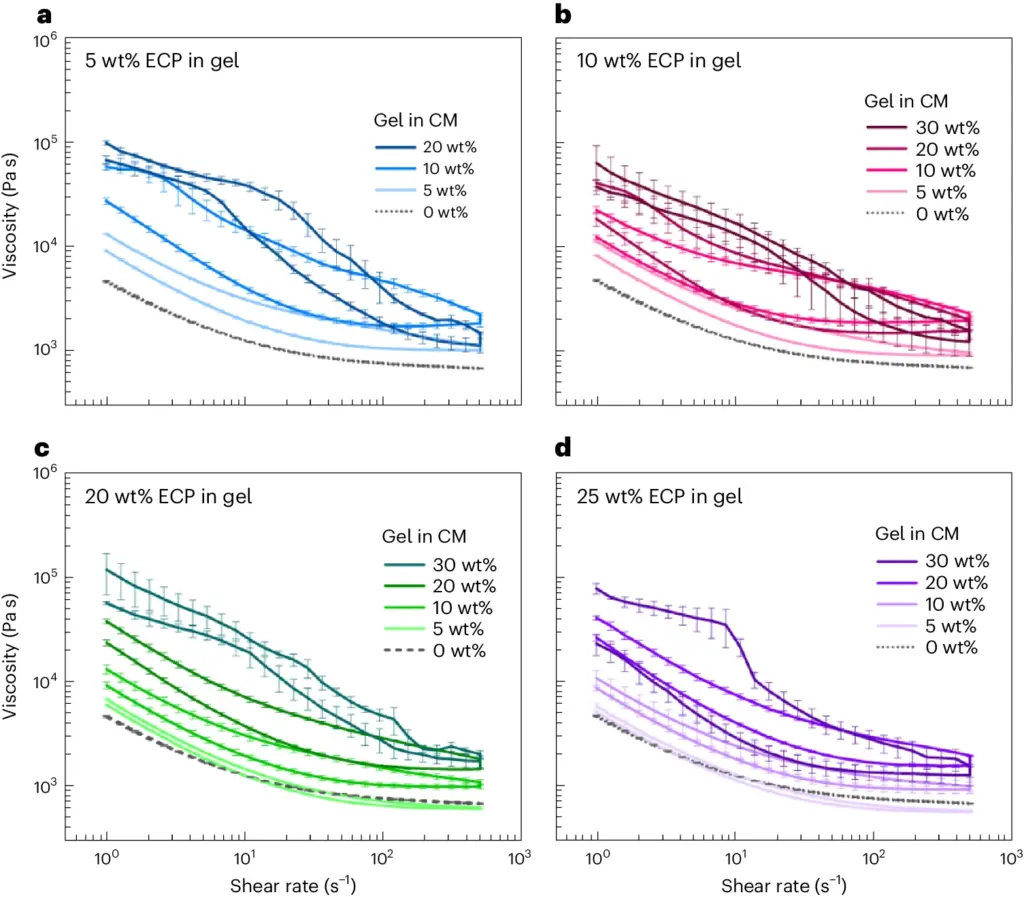

To confirm their theory, the scientists conducted a shear assay to quantify the changes in viscosity as a result of shear stress (think of when you rub lotion or sunscreen on your arm – force that is applied parallel to the surface). The viscosity would reflect the changing physical state from the glossy droplets to the powder crumble and allow for a more accurate comparison of their individual recipes. The assay also allows the scientists to apply a large amount of stress to the sample and determine the Newtonian (or non-Newtonian) physics of the chocolate. Their assay confirmed shear thinning behavior (low viscosity under high stress) for their low gel samples, which changed at the 10% endocarp concentration where a fibril network started to form and increased the viscosity of the chocolate. Upon 20% endocarp concentration, the fibril network was irreversible and corresponded with the phase inversion from drops to crumbles of their chocolate, confirming their theory.

But what about the most important aspect of the study-sweetness?! How did their whole-fruit chocolate compare to commercial options in terms of sweetness? To conduct this survey in a simple and controlled manner, the scientists performed a two-alternative forced-choice assay with two batches of their whole-fruit chocolate (WFC) compared to some powder-sugar sweetened chocolates that mimicked conventional dark chocolate. This meant that the 44 tasters would have to pick between the WFC or the commercial representative – no indecisiveness here! – but are presented with random, unlabeled chocolate. Sorta like a best pie competition with 44 judges, but there were only two entries, and they baked the same pie!

Compared to unsweetened chocolate, their whole-fruit chocolate bars were perceived as sweeter, and one of their batches was even considered as sweet as conventional dark chocolate. However, their second batch was noted to be “bitter and acidic,” which decreased overall sweetness perception. As the sugar content was quantified to be the same between batch 1 and batch 2, the scientists hypothesized that it was an increase in fat content that explained the taste difference since certain fats can suppress the bitter flavor.

While the study investigated a new way to incorporate sweetness into the chocolate, the resulting flavor is harder to determine – this can be influenced by the fermentation period of the beans after harvest and also post-harvest roasting. Incorporating more fermented cocoa beans may hurt this process as the fat content is slightly reduced, while roasted beans have lower acidity and could improve their sweetness perception. Overall, the scientists’ new whole-fruit chocolate, combined with their final life cycle assessment that shows substantial reduction in land and water use, highlights a new avenue to make a fan favorite confection more responsibly.