Article Title: Bottlebrush Bridge between Soft Gels and Firm Tissues

Authors: Andrew N. Keith, Mohammad Vatankhah-Varnosfaderani, Charles Clair, Farahnaz Fahimipour, Erfan Dashtimoghadam, Abdelaziz Lallam, Michael Sztucki, Dimitri A. Ivanov, Heyi Liang, Andrey V. Dobrynin, and Sergei S. Sheiko

Journal: ACS Central Science

Year: 2020

DOI: 10.1021/acscentsci.9b01216

Living tissues found in animals have a very unique quality – at rest, they are soft and malleable. Put them under a bit of pressure, and they quickly change from being quite elastic, to very stiff and resistant to being deformed. This behaviour is called “strain-stiffening”, because tissues become stiff when put under strain. Strain-stiffening behaviour is a key defense mechanism of muscles, ligaments, and even fats. Rapidly increasing their rigidity in response to pressure stops tissues from rupturing, meaning we can avoid pulling muscles and spraining ankles every time they’re put under a bit of force. This property is highly sought after in the fields of soft robotics, wearable electronics, tissue engineering, and surgery, because synthetic materials would be able to tolerate the same movement that tissues in the human body are capable of without being damaged.

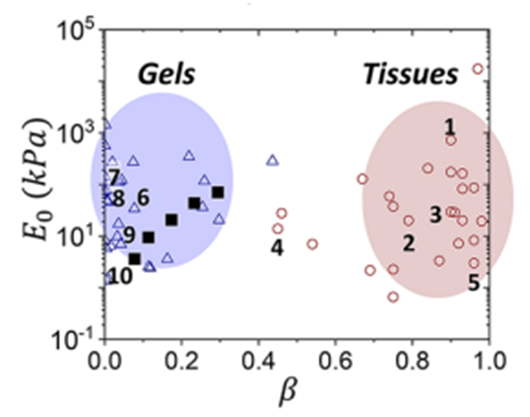

Up until this point, the strain-stiffening behaviour of living tissues has been near impossible to replicate with synthetic materials. Synthetic tissues are usually made up of semi-firm gels. These gels are made up of long, flexible polymer networks, which are swelled with a liquid to create softness. Synthetic alternatives imitate the softness of real tissues, but none of the firmness. As seen in Figure 1 below, previous tissue mimics have not been able to create a material that is both soft and firm like living tissues.

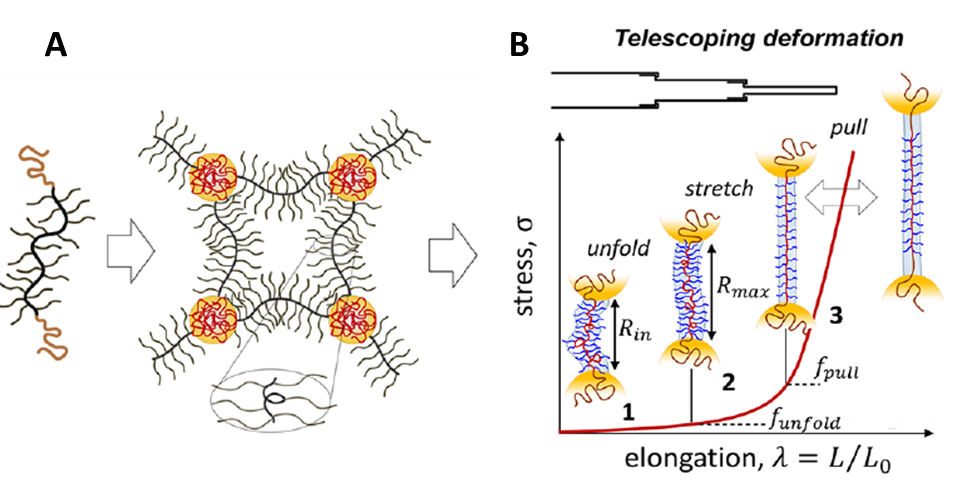

Sheiko and co-workers have finally been able to bridge this gap in a new paper published in ACS Central Science. They achieved this by using a network consisting of bottle brush and linear polymers. Polymers are long, flexible chains consisting of identical units joined together. You can think of a linear polymer as a bit like cooked spaghetti – they are made up of a single chain forming a line, and are highly flexible, preferring to remain in coiled positions rather than stretched positions. Bottle-brush polymers are a little bit different. To visualise a bottlebrush polymer, consider the bottlebrush flower shown in Figure 2. It has a stem at its centre, with flower buds branching of the centre to form a dense, cylindrical shape. Bottlebrush polymers have a linear backbone, like the flower stem. Side chains come off this backbone in all directions, creating the cylindrical shape in much the same way as the bottlebrush flower. The side chains on a bottlebrush polymer also prevent it from coiling up like a linear polymer, meaning it prefers to stay in a reasonably elongated position. Sheiko and co-workers created linear-brush-linear block copolymers. Block copolymers have two or more unique polymer blocks attached together. In this case, the bottlebrush is in the middle (shown in black), capped with two coiled linear polymers at either end (shown in brown).

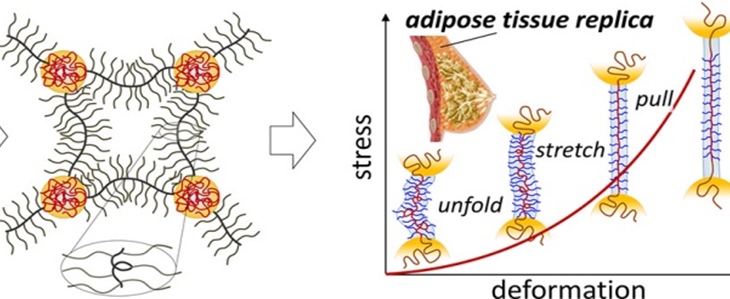

These polymers assemble by themselves into polymer networks that exhibit strain-stiffening behaviour similar to living tissues. This comes from what the authors describe as “telescoping deformation” that occurs when the network is put under strain. This telescoping deformation mimics the strain-stiffening behaviour caused by the unfolding and stretching of microfibril networks in collagen, which is the main structural protein in connective tissues in our bodies. In the polymer networks, the soft elasticity comes from the unfolding and subsequent stretching of the bottlebrush polymers. Bottlebrush polymers tend not to coil up because their side chains keep them elongated, so straightening them out to their full length doesn’t require that much force. This means at this stage, the polymer networks stay soft and malleable, like real tissues. Stretching beyond that length requires much more force, as does stretching coiled linear polymers, since they prefer to stay curled up. This is where the strain-stiffening behaviour starts, since the polymers resist being pulled beyond the full length of the bottlebrush polymers.

When tested against other living tissues, the polymer networks described here show very similar strain-stiffening behaviour to fatty tissues, and are biocompatible with other cells according to preliminary studies. These polymer networks also contain no solvents, whereas traditional silicone implants contain liquid that can slowly leach into the body over time. Each type of tissue has slightly different properties, so a synthetic alternative for fatty tissue won’t mimic the properties of muscles accurately. However, having a synthetic alternative for fatty tissue could potentially provide new options in reconstructive surgery. For example, each year in Australia, over 19,000 women are diagnosed with breast cancer. Some of these women choose to have their breasts removed as part of their treatment, and have breast reconstructive surgery afterwards. This usually requires either using a silicone implant or tissue from another part of the body. Tissue from other parts of the body can more accurately recreate the original breast tissue, so having synthetic tissues that imitate real tissues could help provide more alternatives for people requiring reconstructive surgery.

The creation of these novel polymer networks is the first instance of a material that can accurately mimic the strain-stiffening behaviour of living fat tissues. Since different tissues all have slightly different strain-stiffening parameters, there’s still a lot of work that needs to be done to create synthetic materials that accurately mimic these tissues. Developing materials that mimic the properties of muscles, ligaments, skin, and other tissues would be a huge step forwards in tissue engineering and towards creating biomedical devices that can help diagnose, monitor, and treat different human injuries and illnesses.